Compostable cups with lids changing the future

Compostable cups with lids are changing how businesses approach single-use tableware.

-

The global market for compostable cups is growing at nearly 10% per year, with demand rising in cafes, fast-food chains, and beverage outlets.

-

Major brands now use plant-based materials and invest in new designs to meet stricter regulations and consumer preferences for eco-friendly dining.

Jolly Chef responds to this demand by offering practical, stylish solutions that help event planners and businesses reduce waste and improve sustainability.

Key Takeaways

-

Compostable cups with lids break down quickly in industrial composting, reducing landfill waste and supporting sustainability goals.

-

These cups use renewable plant-based materials like PLA and bagasse, offering safe, durable options for hot and cold drinks.

-

Certified compostable cups meet strict standards, helping businesses ensure product quality and food safety.

-

Using compostable cups lowers carbon footprints and fits well in circular economy systems that recycle nutrients back to soil.

-

Challenges like limited composting facilities and higher costs exist, but education and bulk buying can improve adoption and affordability.

Compostable Cups with Lids

What They Are

Compostable cups with lids offer a sustainable alternative to traditional single-use cups. These products break down into natural components within months when processed in commercial composting facilities. Unlike plastic cups, which can remain in landfills for centuries, compostable cups with lids decompose quickly and do not leave harmful residues. Businesses and event planners choose these cups to reduce waste, comply with plastic bans, and enhance their brand reputation. Many consumers now prefer sustainable products, making compostable cups with lids a smart choice for cafes, restaurants, and catering companies.

Compostable cups enrich soil health and help lower greenhouse gas emissions. They support sustainability goals and demonstrate a commitment to environmental responsibility.

Materials

Manufacturers use renewable, plant-based materials to produce compostable cups with lids. The most common materials include PLA (polylactic acid), bagasse, and paper with biodegradable coatings. PLA comes from corn starch or bamboo and works best for cold beverages. Bagasse, made from sugarcane pulp, provides strength and compostability for both hot and cold drinks. Some cups use recycled plant-based materials, promoting a circular economy and further reducing waste.

|

Material Type |

Description |

Usage |

|---|---|---|

|

PLA (Polylactic Acid) |

Made from corn starch, clear, rigid |

Cold beverages in cafes |

|

Bagasse |

Sugarcane pulp, sturdy, biodegradable |

Hot and cold drinks |

|

Paper with Biodegradable Coatings |

Paper cups with compostable coatings |

Cold drinks |

|

Recycled Plant-Based Materials |

Recycled paper and plant inputs |

Emerging waste reduction |

Jolly Chef uses these advanced materials to create high-quality, compostable cups with lids. Their products are freezer safe, light, and strong, offering the same convenience as plastic without the environmental drawbacks.

Certifications

Certifications help businesses and consumers identify genuine compostable cups with lids. In North America, the BPI (Biodegradable Products Institute) certification confirms compliance with ASTM D6400 or D6868 standards for industrial compostability. In Europe, the EN 13432 standard and Seedling logo verify that products meet strict compostability requirements. TÜV Austria offers OK Compost Industrial and OK Compost Home certifications, clarifying whether products are suitable for commercial or home composting. Food safety certifications, such as FDA in the USA and LFGB in Germany, ensure that materials are safe for contact with beverages.

|

Certification |

Region |

Purpose and Importance |

|---|---|---|

|

BPI Certified |

North America |

Confirms compliance with ASTM standards for industrial compostability |

|

EN 13432 / Seedling |

Europe (EU) |

Mandatory EU standard for compostability labeling |

|

OK Compost Industrial |

Europe/Global |

Clarifies industrial composting conditions and end-of-life disposal |

|

OK Compost Home |

Global |

Certification for home compostability |

|

FDA / LFGB |

North America / Europe |

Ensures food safety for beverage contact |

Jolly Chef demonstrates a strong commitment to eco-friendly options by offering certified compostable cups with lids. Their products meet recognized standards, making them a reliable choice for businesses seeking sustainable tableware solutions.

Environmental Impact

Waste Reduction

Compostable cups with lids help businesses and event planners reduce landfill waste. These cups, made from plant-based materials like PLA, break down in industrial composting facilities within 90 to 180 days. Conventional plastic cups can remain in landfills for over 450 years. Many companies, including Starbucks, have switched to compostable cups to meet sustainability goals and lower landfill fees. Businesses report improved waste management when they pair compostable cups with composting programs. Regulatory trends and consumer demand encourage the adoption of compostable products, supporting waste reduction efforts.

-

Compostable cups decompose quickly in the right facilities.

-

Businesses see lower landfill costs and better waste management.

-

Major brands use compostable cups to meet environmental targets.

Jolly Chef’s biodegradable and compostable product lines offer practical solutions for waste reduction. Their products help organizations achieve sustainability goals and demonstrate environmental responsibility.

Carbon Footprint

The carbon footprint of compostable cups with lids is lower than that of traditional plastic or paper cups. Paper cups require deforestation and energy-intensive processing, which increases their carbon emissions. Plastic cups have a lower production footprint but cause long-term harm through microplastic pollution and persistence in the environment. Compostable cups, especially those coated with PLA, use renewable resources like corn starch or sugarcane. These cups decompose faster and reduce carbon emissions during production.

|

Cup Type |

Production Impact |

Decomposition Time |

Environmental Risk |

|---|---|---|---|

|

Plastic |

Low |

450+ years |

Microplastics, pollution |

|

Paper |

High |

Up to 20 years |

Methane, recycling issues |

|

Compostable (PLA) |

Lower |

1-6 months |

Minimal, if composted |

Proper disposal is important. Compostable cups need industrial composting to realize their environmental benefits. Jolly Chef’s compostable cups with lids help businesses lower their carbon footprint and support responsible sourcing.

Circular Economy

Compostable cups with lids play a key role in the circular economy for the food service sector. These cups, made from renewable materials, break down in industrial composting and return nutrients to the soil. Large events and major brands, such as Starbucks and Costa Coffee, have adopted compostable cups and collaborate with composting facilities to manage waste effectively. Festivals and municipal initiatives show that compostable packaging can divert over 90% of event waste from landfills.

-

PLA cups reduce landfill dependency and support sustainable farming.

-

Compostable packaging works well in closed-loop systems, where food waste and packaging are collected together.

-

Proper labeling and sorting maximize recycling and minimize contamination.

-

Municipal programs, like Milan’s vented bins and compostable bags, increase food waste collection and produce quality compost for farmers.

Jolly Chef’s compostable product lines align with circular economy principles. Their solutions help businesses close the loop on waste, regenerate natural resources, and build greener supply chains.

Practical Benefits

Convenience

Compostable cups with lids offer many advantages for food service businesses and event planners. Their disposable nature simplifies cleanup after gatherings, saving time and labor. Many users report that lightweight and durable materials make these cups easy to handle and transport. Individually wrapped cups provide a hygienic solution, reducing the need for washing and minimizing the risk of contamination. Machine-sealed packaging allows for efficient storage and quick access during busy events. Plant-based materials support eco-friendly disposal, helping businesses meet sustainability goals while maintaining operational efficiency.

-

Disposable design streamlines post-event cleanup.

-

Lightweight construction makes handling and serving easier.

-

Hygienic packaging supports safe food service.

-

Eco-friendly materials align with business sustainability targets.

Safety

Safety remains a top priority for businesses serving food and beverages. Compostable cups with lids made from bagasse pulp and PLA biopolymer offer high leak resistance and heat tolerance. These features help prevent spills and maintain beverage quality, even with hot drinks. Unlike some plastic cups, compostable options do not release harmful chemicals when heated. Bagasse-based cups can withstand microwave temperatures up to 200°F for short periods, making them suitable for reheating. Secure lids fit tightly, reducing the risk of leaks during transport and service.

|

Feature |

Paper Cups |

Plastic Cups |

Bagasse Pulp Cups (Compostable) |

|---|---|---|---|

|

Heat Resistance |

Medium |

Low-Medium |

High |

|

Leak-proof |

Medium |

High |

High |

Performance

Businesses evaluate compostable cups with lids using several performance metrics. Visual inspections check for cracks, dents, and print quality. Structural integrity tests measure leak resistance and sturdiness under pressure. Dimensional accuracy ensures lids fit properly, preventing spills. Functional testing includes heat retention and capacity verification. Laboratory tests confirm safety by checking for heavy metals and microorganisms. These standards help companies select reliable products that meet customer expectations for durability and usability.

-

Visual and structural inspections confirm product quality.

-

Leak and heat tests ensure safe use with hot and cold drinks.

-

Laboratory checks verify compliance with safety standards.

Jolly Chef Customer Stories

Jolly Chef customers often share positive experiences using compostable cups with lids at events and in business settings. Event planners appreciate the convenience and elegant design, which enhance presentation and simplify cleanup. Caterers report that the leak-resistant and microwave-safe features allow them to serve a variety of beverages without worry. Families hosting gatherings find the cups easy to use and dispose of, reducing stress during preparation and cleanup. Many customers note that Jolly Chef’s eco-friendly options help them meet sustainability goals while maintaining high standards for quality and appearance.

“Jolly Chef’s compostable cups made our wedding reception cleanup effortless. Guests loved the stylish look, and we felt good knowing we chose an eco-friendly solution.” – Event Planner

Challenges

Composting Facilities

Many businesses face challenges with composting infrastructure. Most compostable cups with lids require industrial composting facilities to break down properly. These facilities use high heat and moisture to process materials like PLA and bagasse. Only a small percentage of cities offer commercial composting services. Rural areas and smaller towns often lack access, slowing adoption. Some recycling centers cannot process cups with biodegradable coatings, leading to low recycling rates. Businesses must coordinate with local composting providers to ensure proper disposal. Consumer confusion about where to throw compostable cups also reduces effectiveness.

-

Only 9% of global plastic waste is recycled.

-

Just 1 in 400 paper cups is recycled due to contamination and facility limitations.

-

Many compostable cups end up in landfills, where they do not decompose as intended.

Tip: Businesses can improve outcomes by partnering with composting facilities and educating staff on correct sorting practices.

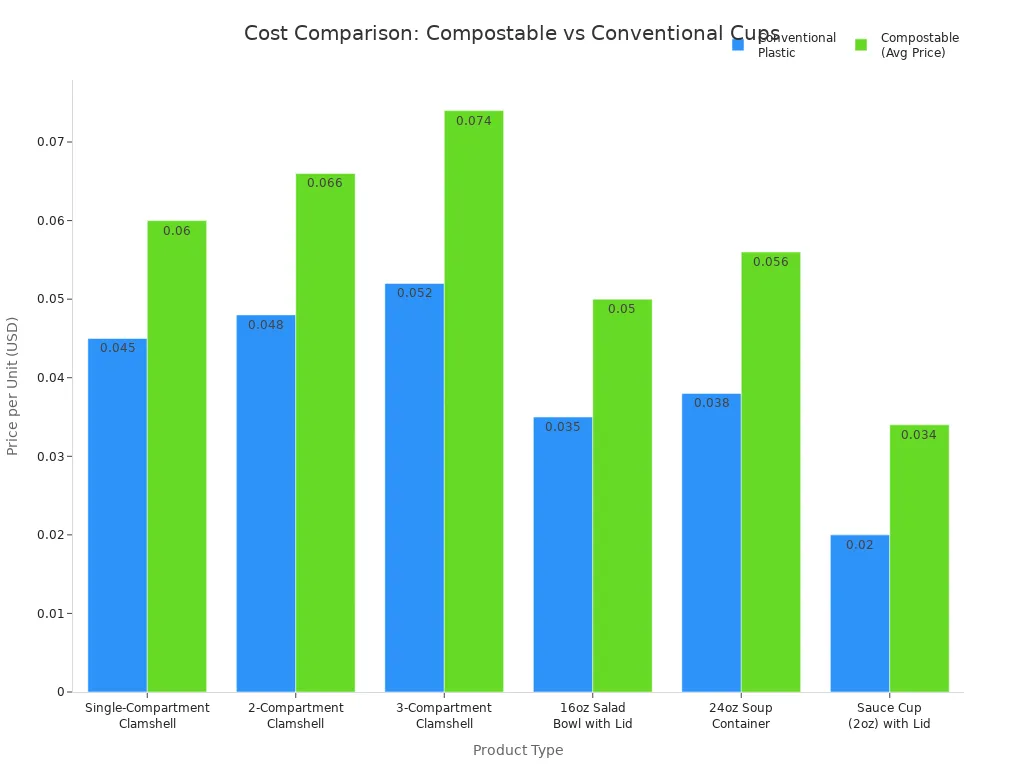

Cost

Cost remains a significant factor for enterprises and event planners. Compostable cups with lids typically cost 30% to 50% more than conventional plastic options. Material, certification, and region influence pricing. Bulk purchasing can help reduce costs, but compostable products still average 1.3 to 1.5 times the price of traditional disposables. This price difference affects procurement decisions, especially for large-scale events or high-volume operations.

|

Product Type |

Plastic Price (per unit) |

Compostable Price Range (per unit) |

Notes on Material and Features |

|---|---|---|---|

|

Single-Compartment Clamshell |

$0.045 |

$0.055–$0.065 |

Bagasse pulp, PFAS-free |

|

16oz Salad Bowl with Lid |

$0.035 |

$0.045–$0.055 |

Kraft paper, PLA lining |

|

Sauce Cup (2oz) with Lid |

$0.020 |

$0.030–$0.038 |

Bagasse or PLA |

Awareness

Consumer and employee awareness plays a key role in proper disposal and composting. Many people believe paper packaging is always biodegradable, which leads to improper sorting. Compostable cups need specific conditions to break down, not regular trash or recycling bins. Businesses benefit from clear signage, staff training, and direct communication with customers. These efforts help prevent compostable cups from ending up in landfills. Environmentally aware consumers prefer certified compostable products, motivating companies to adopt sustainable options.

-

Effective waste management strategies ensure proper disposal.

-

Education through signage and social media encourages correct use.

-

Businesses can phase out traditional cups by introducing compostable options alongside awareness campaigns.

Note: Addressing misconceptions about compostable cups helps businesses achieve sustainability goals and improve supply chain efficiency.

Future Trends

Innovations

Manufacturers continue to develop new designs and materials for compostable cups with lids. Molded pulp fiber and bio-based polymers now offer improved durability and leak resistance. Some companies have introduced 100% plastic-free biodegradable cups with integrated spill-proof lids. These innovations help businesses serve beverages safely while meeting sustainability goals. Advances in thermal stability and antimicrobial coatings support hot and cold drink applications. Startups and established brands invest in AI-driven design optimization and IoT-enabled supply chain management, which improve product performance and traceability.

Note: Innovative lid designs reduce spills and enhance customer satisfaction at busy events and cafes.

Adoption

Major food service providers have increased their use of compostable cups with lids. Starbucks, McDonald's, and Dunkin' Donuts now offer sustainable packaging options in many locations. The North America beverage cups and lids market reached $2.82 billion in 2023, with steady growth expected through 2030. Consumer demand and regulatory pressure drive this trend. In the United States, adoption rates rise about 5% each year, supported by strong regulations and new lid designs. Coffee shops and quick-service restaurants in Canada and Mexico also shift toward biodegradable solutions.

|

Region |

Adoption Trend & Drivers |

Market Growth (CAGR) |

Key Factors |

|---|---|---|---|

|

United States |

Steady increase driven by consumer demand and regulations |

~5% (to 2028) |

Eco-friendly packaging, regulatory support, innovation in lid design |

|

Canada |

Rapid adoption in coffee shops and restaurants, focus on biodegradable lids |

4.5% (to 2028) |

Environmental awareness, government regulations, investment in innovative lid designs |

|

Mexico |

Shift toward biodegradable and compostable materials, especially in urban centers |

N/A |

Regulatory emphasis, consumer preference shift, urban market drivers |

Industry Transformation

Government policies play a major role in transforming the disposable cup industry. States like California ban expanded polystyrene foam, pushing businesses to choose compostable alternatives. Vermont requires compostable produce stickers to reduce contamination. Local initiatives, such as Seattle’s Reuse Seattle program, offer rebates and support for switching to reusable and compostable cups. These efforts encourage companies to adopt sustainable products and improve waste management. The market for paper cup lids in the United States is projected to grow at 5.9% CAGR from 2025 to 2035, reflecting strong momentum for compostable solutions.

Jolly Chef envisions a future where every event and dining experience uses practical, elegant, and eco-friendly tableware. The brand invests in certified compostable cups with lids, helping businesses meet procurement needs and sustainability targets. By focusing on supply chain efficiency and product reliability, Jolly Chef supports industry transformation and sets new standards for sustainable dining.

Compostable packaging solutions have transformed the food service industry by reducing waste and lowering carbon emissions. Businesses see measurable benefits, such as a 72% decrease in packaging waste and 18% savings in waste management costs.

Key reasons for choosing eco-friendly tableware include safer materials, faster decomposition, and strong consumer demand for sustainable options. Supporting brands like Jolly Chef helps companies meet regulatory goals and build a positive reputation.

FAQ

What makes compostable cups with lids a smart choice for businesses?

Compostable cups with lids help companies meet sustainability goals. They reduce landfill waste and support green branding. Many businesses choose these products to comply with regulations and show environmental responsibility.

How do compostable cups with lids benefit event planners?

Event planners use compostable cups with lids for easy cleanup and quick setup. These cups save time and reduce labor costs. Their elegant design also improves event presentation.

Are compostable cups with lids cost-effective for large orders?

Bulk purchasing lowers the unit price of compostable cups with lids. Many suppliers, like Jolly Chef, offer discounts for high-volume orders. This helps businesses manage budgets while choosing eco-friendly options.

Can compostable cups with lids handle both hot and cold drinks?

Yes. Many compostable cups with lids use bagasse or PLA materials. These materials provide heat resistance and leak protection. Businesses can serve hot coffee or cold beverages without worry.