Sustainable Bulk Packaging Shifts

Sustainable packaging trends reshape food and beverage packaging in 2025 with rapid adoption across global markets. The sector expects a compound annual growth rate of over 7 percent, driven by innovations such as recycled plastics and reusable containers. Businesses select sustainable solutions to meet regulatory standards and consumer demand, lowering greenhouse gas emissions and waste. Jolly Chef demonstrates its commitment to sustainability by offering compostable products that align with modern packaging requirements, providing practical solutions for both companies and individuals.

Key Takeaways

-

Sustainable bulk packaging uses eco-friendly materials like compostable containers and recyclable plastics to reduce waste and protect the environment.

-

Mono-material and refillable packaging simplify recycling and help companies meet regulations while saving costs and supporting circular economy goals.

-

Smart and minimalist packaging designs improve food safety, reduce material use, and streamline supply chains for better efficiency.

-

Consumers prefer packaging that is convenient, transparent, and eco-friendly, which builds trust and loyalty for brands.

-

Businesses can succeed by collaborating with suppliers, measuring impact, and adopting innovative, sustainable packaging solutions that meet future market demands.

Sustainable Packaging Trends

Eco-Friendly Materials

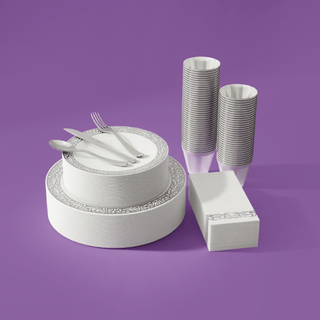

Sustainable packaging trends in 2025 show a strong shift toward eco-friendly materials. Companies in the food and beverage packaging industry now favor compostable, biodegradable packaging, and bio-based alternatives. These materials include PLA and PHA bioplastics, kraft paper, corrugated fiberboard, and plant-based films such as seaweed wraps and corn-derived coatings. Businesses choose these solutions to conserve natural resources and reduce reliance on fossil fuels and virgin plastics. Eco-friendly packaging also lowers waste generation, supports responsible consumption, and helps preserve ecosystems.

Jolly Chef’s White 3-Compartment Microwave-Safe Compostable Take Out Food Containers demonstrate innovation in this area. Made from renewable sugarcane, these containers are 100% biodegradable and compostable. They offer leak-proof storage and microwave safety, making them practical for office lunches, catering, and picnics. The double-locking clasp design ensures food remains fresh during transport. Companies benefit from these containers by meeting consumer demand for zero-waste packaging systems and reducing landfill burden.

Note: Eco-friendly bulk packaging helps lower pollution and greenhouse gas emissions, supporting business goals for sustainability and environmental responsibility.

-

Key eco-friendly packaging trends:

-

Adoption of compostable and biodegradable packaging for short-shelf-life products

-

Use of recyclable rigid and flexible packaging

-

Preference for bio-based materials and natural textures

-

Mono-Material Solutions

Mono-material solutions have become essential in food and beverage packaging. Brands now use single plastic types such as polyethylene, polypropylene, and PET to create recyclable packaging. This approach simplifies recycling processes and reduces contamination in recycling streams. Companies respond to stricter regulations like Extended Producer Responsibility policies and bans on single-use plastics by adopting recyclable mono-materials. Technological advances in barrier coatings and high-performance films improve food preservation, making these solutions viable for bulk packaging.

Mono-material packaging supports circular economy goals and reduces waste sent to landfills. Investments in chemical and mechanical recycling technologies enable production of food-grade recycled PET. Consumer awareness and brand sustainability efforts accelerate the adoption of recyclable packaging, contributing to improved recyclability in the sector.

-

Advantages of mono-material solutions:

-

Easier recycling and reduced waste

-

Compliance with government regulations

-

Enhanced food preservation through advanced coatings

-

Support for circular economy initiatives

-

Refillable and Returnable Systems

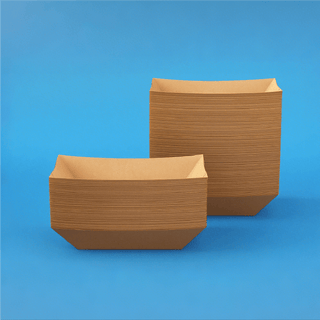

Refillable and returnable systems represent a major trend in sustainable packaging. These models include Loop systems and bulk-store refill options, allowing consumers to reuse packaging multiple times. The global reusable and refillable packaging market reached $46.59 billion in 2025 and is projected to grow to $64.25 billion by 2034. Regulatory frameworks in the EU and France mandate increased adoption of reusable beverage packaging, driving innovation and market expansion.

Consumer acceptance of refillable systems remains high. Over half of consumers prioritize reusable or refillable packaging in purchasing decisions, and nearly half use reusable products weekly. Gen Z shoppers actively seek sustainable brands, influencing market growth. Businesses that transition to reusable systems unlock significant economic opportunities and address procurement pain points by reducing single-use packaging costs.

|

Evidence Aspect |

Details |

|---|---|

|

Consumer Priority |

56% of consumers prioritize reusable or refillable packaging in purchasing decisions. |

|

Consumer Usage |

Nearly 50% of consumers use reusable products weekly, indicating strong acceptance. |

|

Gen Z Sustainability Preference |

69% of Gen Z shoppers actively seek sustainable brands. |

|

Market Size (2025) |

Global reusable and refillable packaging market valued at $46.59 billion. |

|

Market Projection (2034) |

Projected to grow to $64.25 billion with a CAGR of 4.1%. |

|

EU Regulatory Targets |

10% reusable beverage packaging by 2030; 40% by 2040 mandated by EU Packaging Regulation. |

|

Other Regulations |

France mandates 10% reusable packaging by 2026. |

|

Economic Opportunity |

Transitioning 20% of single-use packaging to reusable systems could unlock $10 billion. |

|

Drivers |

Consumer demand, especially among younger demographics, and regulatory frameworks. |

|

Challenges |

Consumer behavior change, safety concerns, infrastructure costs. |

|

Innovations |

Advances in materials, smart technology, and design facilitating scaling. |

Refillable and returnable packaging trends support zero-waste goals and offer practical solutions for bulk food and beverage packaging. Companies gain supply chain advantages and cost savings by reducing single-use packaging and investing in scalable systems.

Drivers of Change

Consumer Demand

Consumer preferences shape trends in bulk packaging. Shoppers expect products that align with zero-waste principles and support a cleaner environment. Many buyers choose packaging that offers convenience and reduces waste. Businesses respond by offering solutions that meet these expectations, such as compostable containers and refillable systems. Companies see increased loyalty when they provide packaging that fits modern lifestyles and values. Gen Z and millennial consumers drive demand for innovative packaging that supports environmental impact reduction.

Regulations

Governments introduce new rules to guide packaging trends and protect the environment. These regulations push companies to adopt recyclable, compostable, and biodegradable materials. The following table outlines key regulations in major regions and their impact on bulk packaging:

|

Region |

Key Regulations and Drivers |

Impact on Sustainable Bulk Packaging |

|---|---|---|

|

Asia Pacific |

India’s Plastic Waste Management Rules; China’s ban on single-use plastics |

Strict bans and rules push companies to adopt recyclable, biodegradable, and compostable packaging materials. |

|

North America |

California's Plastic Pollution Prevention and Packaging Producer Responsibility Act; Extended Producer Responsibility (EPR) frameworks |

Mandates recyclable or compostable packaging; companies responsible for full lifecycle; drives innovation in materials. |

|

Europe |

European Green Deal; EU Packaging and Packaging Waste Directive (PPWD); Single-Use Plastics Directive |

Mandates reduced plastic use, improved recyclability, and circular economy models; strong ESG expectations. |

|

General |

Government bans and taxes on single-use plastics; certifications like FSC, BPI, OK Compost |

Pushes businesses to greener alternatives and adoption of sustainable packaging certifications. |

|

Market Trend |

Rise of e-commerce increasing packaging waste and consumer demand for eco-conscious delivery options |

Drives demand for sustainable shipping materials and packaging solutions to reduce environmental impact. |

These regulations encourage companies to innovate and invest in new packaging solutions. Businesses that adapt quickly gain a competitive edge and avoid penalties.

Environmental Impact

Packaging choices affect the environment in several ways. Companies that switch to sustainable bulk packaging see measurable improvements.

-

Landfill waste decreases as upcycling and reuse become common, supporting a circular economy.

-

Reusable packaging systems reduce single-use waste and encourage lasting changes in consumer behavior.

-

Businesses lower waste disposal costs by using recyclable or compostable materials.

-

Lighter, compact packaging improves supply chain efficiency and reduces transportation emissions.

-

Using biodegradable, compostable, recyclable, and reusable materials minimizes pollution and waste.

-

Strategies such as reducing packaging material and using recycled content lower environmental footprints throughout the product lifecycle.

Companies that focus on these trends improve their brand reputation and meet growing expectations for environmental responsibility.

Innovations in Food and Beverage Packaging

Smart Packaging

Smart packaging has transformed how companies manage food and beverage packaging. Businesses now use advanced technologies to monitor product quality, improve safety, and streamline supply chains. These solutions help companies track products, reduce waste, and respond quickly to issues.

-

Time–Temperature Indicators (TTIs) monitor temperature during storage and transport. They alert users if products experience unsafe conditions, helping maintain quality.

-

RFID and NFC tracking systems enable real-time tracking of bulk shipments. Companies use these tools to trace products, reduce counterfeiting, and manage recalls efficiently.

-

Gas and quality sensors detect freshness by monitoring gas composition, humidity, and pH inside packaging.

-

Intelligent indicators with color-changing labels provide visual cues about product freshness or ideal consumption times.

-

Active packaging components, such as oxygen and CO2 scavengers, extend shelf life and maintain product quality.

-

Biosensors, IoT, and nanomaterials further enhance food safety and quality monitoring.

These smart packaging technologies address the need for better monitoring and quality assurance in bulk food and beverage packaging. Jolly Chef’s containers, with their leak-proof design and secure double-locking clasp, support safe transport and storage, aligning with the industry’s shift toward smarter, more reliable packaging.

Companies that adopt smart packaging gain a competitive edge by improving traceability and reducing losses from spoilage or recalls.

Minimalist Design

Minimalist design has become a key trend in packaging. Companies focus on reducing excess materials and simplifying packaging structures. This approach leads to less waste and lower costs, especially for bulk products.

-

Minimalist packaging uses right-sized boxes and eliminates unnecessary layers. This reduces shipping volume and weight, cutting transportation costs.

-

Streamlined packing processes improve operational efficiency and reduce handling time.

-

Lightweight yet durable materials offer long-term savings, even if initial costs are higher.

-

Simple designs help companies comply with regulations and avoid extra fees.

Jolly Chef’s White 3-Compartment Microwave-Safe Compostable Take Out Food Containers showcase minimalist design principles. The containers use a three-compartment layout to organize food efficiently, while the sturdy sugarcane material ensures durability without extra bulk. Customers appreciate the easy-to-use design, which simplifies meal prep and cleanup for events and catering.

“The containers made our event setup quick and cleanup effortless. Guests loved the organized compartments and sturdy feel.”

— Jolly Chef customer review

Minimalist packaging supports cost reduction and operational efficiency, making it a practical choice for businesses managing large-scale food and beverage packaging needs.

Flexible Packaging

Flexible packaging offers versatility and efficiency for bulk food and beverage packaging. Companies choose flexible options for their ability to fit various product shapes and sizes, which helps maximize storage and reduce shipping costs. Flexible materials, such as pouches and wraps, protect products while using less space than rigid containers.

Businesses benefit from flexible packaging in several ways:

-

It adapts to different product types, from liquids to solids.

-

It reduces material usage and transportation expenses.

-

It supports high-speed filling and sealing processes, improving productivity.

Jolly Chef’s product line includes containers designed for both convenience and flexibility. The microwave-safe and refrigerator-safe features allow users to store and reheat food with ease. Event planners and caterers find these solutions valuable for managing large orders and ensuring food stays fresh during transport.

Flexible packaging solutions help companies respond to changing market demands and streamline their supply chains.

Customer feedback highlights the practical advantages of these innovations. Many users report that Jolly Chef’s containers save time, reduce mess, and provide reliable performance at events and in daily operations.

Business Impact

Cost Efficiency

Businesses seek cost-effective solutions when choosing bulk packaging. Sustainable bulk packaging options, such as those offered by Jolly Chef, provide practical features that help reduce operational expenses. For example, microwave-safe and leak-proof containers minimize food waste and lower the risk of product loss during transport. Bulk purchasing options allow enterprises and event planners to save on unit costs, making large-scale events more affordable. Durable packaging materials also reduce the need for double packing, which cuts down on supply expenses. Companies benefit from streamlined cleanup processes, saving time and labor costs after events or in high-volume food service settings.

Supply Chain

Efficient supply chains play a key role in the success of bulk packaging solutions. Jolly Chef ships products from US-based warehouses, ensuring fast delivery and reliable inventory management for B2B clients. Consistent product quality and availability help businesses avoid delays and maintain smooth operations. Leak-proof and sturdy packaging supports safe transport, reducing the risk of damage during shipping. Flexible packaging options adapt to different food types and storage needs, which simplifies logistics for caterers and merchants. Bulk packaging also allows for easier storage and handling, improving workflow efficiency in busy environments.

Implementation Challenges

Businesses face several challenges when implementing new bulk packaging solutions. These challenges can impact cost, supply chain efficiency, and product performance.

-

Higher costs and complex supply chains for sustainable materials increase production expenses and complicate sourcing.

-

Material limitations affect durability, flexibility, and shelf life, challenging product protection.

-

Consumer perception issues require education to gain acceptance and trust in new packaging.

-

Underdeveloped recycling and waste management infrastructure limits the effectiveness of some packaging materials.

-

Lack of subject expertise among procurement professionals hinders effective sourcing and implementation.

-

Scalability problems arise due to limited availability and inconsistent supply of raw materials.

-

Difficulties in supply chain transparency and monitoring make it hard to verify supplier compliance with standards.

Businesses can address these challenges by investing in supplier partnerships, staff training, and process improvements. Clear communication with suppliers and customers helps build trust and ensures smooth adoption of new packaging solutions.

Consumer Benefits

Sustainable Choices

Consumers increasingly select bulk food and beverage products based on packaging that aligns with their values. Many buyers prefer options that use compostable materials and clear labeling. Jolly Chef’s White 3-Compartment Microwave-Safe Compostable Take Out Food Containers meet this demand by offering reliable performance and organized food storage. These containers use renewable sugarcane, which appeals to buyers who care about responsible sourcing. Studies show that 74% of consumers willingly pay more for eco-friendly packaging, and 67% consider the materials used in packaging when making purchasing decisions. Brands that adopt compostable solutions, such as Jolly Chef, gain loyalty and positive brand perception.

Convenience

Practicality remains a top priority for consumers in bulk packaging. Jolly Chef’s containers simplify meal prep and event management. The three-compartment design keeps food organized, while the double-locking clasp prevents leaks during transport. Microwave and refrigerator safety add flexibility for users who need to store or reheat meals. Customers report that these features save time and reduce mess at events. Many buyers appreciate the ease of disposal, as the containers can be placed in compost bins after use. This convenience supports efficient operations for caterers, event planners, and families.

“Jolly Chef containers made our catering setup smooth and cleanup fast. The sturdy design and organized compartments impressed our guests.”

— Customer review

Trust and Transparency

Transparency in packaging builds trust between brands and consumers. Jolly Chef provides clear information about the materials and disposal methods for its containers. Detailed labeling educates users on composting and recycling, which increases confidence in product choices. Digital tools and transparent reporting assure buyers about sourcing and production processes. Partnerships with suppliers ensure compliance with industry standards. These practices demonstrate a commitment to transparency and strengthen brand credibility. Consumers feel confident when they understand how to use and dispose of packaging responsibly.

-

Transparency practices include:

-

Clear labeling on packaging for disposal instructions

-

Digital traceability tools for sourcing verification

-

Supplier partnerships for compliance and innovation

-

Actionable Steps for Brands

Transition Strategies

Brands moving to sustainable bulk packaging benefit from clear, step-by-step transition strategies. The most effective approach starts with selecting eco-friendly materials such as bioplastics, recycled paper, or compostable films. Companies often reduce excess packaging by right-sizing containers and using lighter materials. Redesigning packaging for easier recycling and consumer use, like adding clear instructions or easy-open features, improves the user experience. Many brands now include recycled content in their packaging, working with recycling facilities to ensure a steady supply. Adopting certified biodegradable or compostable packaging, such as Jolly Chef’s sugarcane-based containers, helps meet business needs for reliable, single-use food storage.

Tip: Brands can implement reusable packaging systems with take-back programs or incentives, which support circular business models and reduce single-use waste.

Supplier Collaboration

Strong supplier relationships help brands overcome procurement challenges. Companies set clear sustainability criteria and use packaging scorecards to track supplier performance. Collaboration with suppliers ensures a consistent supply of high-quality materials and supports innovation in packaging design. For example, Jolly Chef works closely with suppliers to maintain product quality and fast delivery from US-based warehouses. This approach reduces delays and helps businesses manage inventory more efficiently. Brands also benefit from sharing best practices and co-developing new packaging formats that fit specific application scenarios, such as catering or large-scale events.

Measuring Impact

Brands measure the impact of new packaging solutions by tracking key performance indicators. These include cost savings, reduced packaging waste, and improved supply chain efficiency. Companies use digital tools to monitor packaging performance and gather feedback from customers. Clear labeling and transparent communication help users understand how to handle packaging after use. Regular reviews of packaging processes allow brands to adjust strategies and improve results over time. By focusing on measurable outcomes, businesses ensure that their packaging choices deliver real value.

Future Food Packaging Trends

Beyond 2025

The future of food packaging trends points to rapid changes in materials and technology. Companies are exploring plant-based, seaweed-based, and mushroom-based packaging. Edible packaging options are gaining attention for their unique application in reducing waste. Smart packaging technologies, such as freshness sensors, QR codes, and NFC, are expected to reach a market value of $43.6 billion by 2027. These tools help businesses monitor product quality and engage customers. Mono-material packaging will become more common, making recycling easier and supporting corporate goals. Flexible packaging, including stand-up pouches, will continue to grow due to its efficiency and adaptability. Zero-waste systems, like refill stations and returnable packaging, will expand in retail and food service. Companies will also rely more on domestic manufacturing to strengthen supply chains and reduce disruptions.

-

Plant-based, seaweed-based, and mushroom-based materials

-

Smart packaging with sensors and digital features

-

Mono-material and flexible packaging for easier recycling

-

Zero-waste systems and domestic manufacturing

Barriers and Opportunities

Businesses face several barriers as they adopt new packaging solutions. Infrastructure for managing packaging materials varies by region, making it hard to standardize processes. Sustainable materials often cost more and require new supply chains. Companies must balance product protection with the need for eco-friendly options. However, opportunities exist. Paper packaging works well with existing recycling systems, especially for products that do not need high barriers. New technologies, such as compostable and recyclable barrier liners, help brands reduce plastic use while maintaining product quality. Collaboration between brands and suppliers can improve material performance and reduce costs.

|

Barriers |

Opportunities |

|---|---|

|

Inconsistent infrastructure |

Advanced barrier liners for paper packaging |

|

Higher material costs |

Mature recycling systems for paper |

|

Supply chain complexity |

Collaboration for better material performance |

|

Product protection needs |

Dual end-of-life options (recycling, composting) |

Role of Innovation

Innovation drives the next wave of packaging solutions. Reusable packaging systems, supported by digital tools and automation, help companies reduce waste and improve efficiency. Smaller pallets and right-sized containers make shipping and storage easier. IoT and sensor technologies allow real-time tracking and better asset management. Digital twins and AI-driven automation optimize supply chains and packaging operations. These advances help businesses meet changing consumer needs and improve operational performance. Companies that invest in new materials and smart technologies will lead the market as food packaging trends evolve.

Companies that embrace innovation in packaging design and logistics gain a competitive edge in efficiency and customer satisfaction.

Key packaging trends in bulk food and beverage sectors include minimalist design, smart technology, and the use of compostable materials. These trends drive efficiency and support business goals by reducing material use and streamlining supply chains. Jolly Chef’s innovative containers demonstrate how practical features and organized layouts can meet evolving industry needs. Brands can advance by selecting recyclable or compostable materials, collaborating with logistics partners, and educating customers. The next decade will see packaging trends shaped by smart technology and growing demand for efficient, adaptable solutions.

FAQ

What makes Jolly Chef’s bulk packaging suitable for large-scale events?

Jolly Chef designs containers for easy handling, quick setup, and efficient cleanup. The three-compartment layout keeps food organized. Bulk packs help event planners save time and reduce costs.

Are Jolly Chef containers safe for microwave and refrigerator use?

Yes. The containers withstand microwave reheating and cold storage. This feature supports flexible meal prep and storage for catering, offices, and events.

How do Jolly Chef containers help streamline supply chains?

Bulk packaging options reduce ordering frequency and simplify inventory management. US-based warehouses ensure fast delivery and consistent product availability for business clients.

What features prevent leaks and spills during transport?

The double-locking clasp design secures each container. This feature keeps food fresh and prevents leaks, making transport safe and reliable.

Can businesses dispose of Jolly Chef containers easily after use?

Yes. The containers support single-use applications and can be placed in compost bins. This process simplifies post-event cleanup and reduces labor requirements.