To-Go Box Procurement

Choosing the right to go boxes for food is a strategic business decision for any establishment. Owners must balance material performance with food compatibility and company goals. The global market for food packaging items is expanding rapidly, with projections showing a 4.6% annual growth rate through 2034. This boom in the takeout market highlights the need for smart procurement in the food service industry.

This practical guide helps businesses navigate the many types of to go containers available. Options include plastic, paper, aluminum, and eco-friendly containers, each offering unique benefits for convenient food packaging.

Key Takeaways

-

Choose the right to-go boxes for your food. Different foods need different containers. Hot foods need heat-safe boxes. Wet foods need leak-proof boxes.

-

Consider plastic, aluminum, paper, and eco-friendly options. Each material has its own benefits. Plastic and aluminum are good for different temperatures. Paper and eco-friendly boxes help with branding and sustainability.

-

Think about your budget and brand image. Custom boxes can make your brand stronger. Eco-friendly options attract customers who care about the environment. These choices can increase sales.

-

Use a checklist to pick your containers. Match the box to your food's temperature and texture. Make sure the size is right. This helps keep customers happy and food fresh.

PLASTIC AND ALUMINUM CONTAINERS

Plastic and aluminum are foundational materials in the food packaging industry. Plastic alone commands a significant portion of the market, making these materials a primary consideration for any business. Understanding their specific types and procurement factors is key to selecting the right disposable take out food containers.

|

Material Category |

Market Share (2023) |

|---|---|

|

Plastic |

Over 55% |

|

Paper-based |

Gaining traction |

|

Biodegradable Materials |

Sustainable alternative |

|

Aluminum |

Gaining popularity |

COMMON TYPES AND USES

Different plastics serve distinct purposes based on their temperature stability.

-

Polypropylene (PP): This plastic is a popular choice for hot foods. Its higher heat tolerance makes it suitable for microwaveable meals and hot takeout items.

-

Polyethylene terephthalate (PET): You will find PET used for cold applications. It is perfect for salads, cold sandwiches, and beverages. Chemical migration from PET increases with temperature, so it is not intended for heating.

Aluminum foil containers are prized for their excellent heat conduction and retention. They are a staple in catering for serving dishes straight from the oven, such as baked pastas, lasagnas, and roasted meats. Their ability to go from freezer to oven makes them highly versatile.

PROCUREMENT CONSIDERATIONS

Businesses must weigh several factors when choosing between these materials. Cost is a major driver; a standard 24-ounce PP container costs approximately $0.32 per unit. Aluminum production is energy-intensive, which can influence its price point.

Durability is another key aspect. While both materials are sturdy, FDA regulations state that most plastic packaging is not safe for conventional ovens. Aluminum, however, is ideal for freezer-to-oven applications.

Recycling Realities ♻️ Sustainability goals also impact procurement. The recycling rate for PET bottles is around 41.3% in North America. In contrast, the rate for PP is a very low 3%. This difference is a critical consideration for eco-conscious brands.

RESTAURANT TAKEOUT FOOD CONTAINERS

Paper-based products are gaining significant traction in the food service industry. High-quality paper takeout containers offer a sustainable and versatile option for many businesses. They provide an excellent balance of performance and branding potential for modern restaurant takeout food containers.

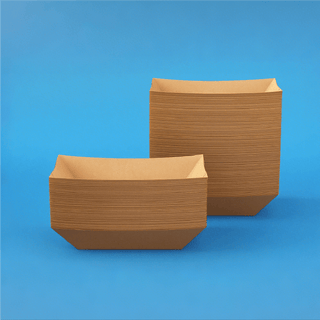

KRAFT PAPER SOLUTIONS

Kraft paper solutions are a popular choice for their durability and eco-friendly appeal. These disposable take out food containers are not just sturdy; they are engineered for performance. Technical specifications ensure they are both leak-proof and oil-resistant.

-

Internal Lining: A polyethylene (PE) or polylactic acid (PLA) coating creates a barrier against grease and liquids.

-

Material Quality: High-strength kraft paper, sometimes up to 300gsm thick, provides structural integrity for wet or oily foods.

A prime example is the Jolly Chef Brown Microwavable Round Kraft Paper Soup Container. Its built-in polyester film makes it waterproof and oil-resistant. The secure lid prevents spills, making it ideal for hot soups and cold food storage. This makes it a great choice for both meal prep and takeout operations.

BRANDING AND CUSTOMIZATION

Paper and cardboard surfaces are perfect for branding. Businesses can print logos and custom designs directly onto their packaging. This transforms a simple box into a powerful marketing tool that enhances the customer experience. For example, the poke franchise NATU Bowl saw a 40% rise in Instagram mentions after switching to high-quality kraft paper packaging. This move resonated with their eco-conscious customers and improved their brand image.

Creating custom paper takeout boxes involves several cost factors. A one-time plate fee of around $330 is common for setting up a 2-3 color logo print. The final unit price for takeout and delivery packaging depends on several elements.

-

Order quantity

-

Intricate structural designs

-

Premium finishes like foil stamping or embossing

-

The number of ink colors used

These factors allow businesses to tailor their packaging to meet both budget and branding goals.

ECO-FRIENDLY CONTAINERS

Businesses increasingly choose eco-friendly containers to meet consumer demand for sustainability. These products offer a responsible alternative to traditional packaging. Besides sugarcane, other popular sustainable materials include bamboo and rice husk. Bamboo is biodegradable and heat-resistant. Rice husk is a low-cost, renewable byproduct of farming. This shift reflects a growing market commitment to environmental stewardship.

SUGARCANE BAGASSE BOWLS

Sugarcane bagasse is a leading material in green packaging. It comes from 100% sugarcane fibers, a byproduct of sugar production. This makes the final products both biodegradable and compostable. These bowls are sturdy and perform well with a variety of foods. They resist oil and soaking, preventing leaks during use with hot or cold items. This makes them ideal for parties, events, and daily takeout service.

Composting Facts 🌿 In a commercial composting facility, bagasse products typically decompose within 45 to 90 days. Many of these products meet strict compostability standards like ASTM D6400 and D6868. These standards ensure the material breaks down safely without leaving toxic residues.

JOLLY CHEF SUSTAINABLE OPTIONS

Aligning a brand with environmental values is a powerful business strategy. Jolly Chef helps businesses achieve this goal by offering award-winning compostable bowls made from sugarcane bagasse. Choosing these high-quality options demonstrates a commitment to sustainability without sacrificing performance. Jolly Chef's products provide the durability and reliability that food service operations need. This allows businesses to offer a superior customer experience while supporting a healthier planet. Host Like a Pro with Jolly Chef Disposable Tableware Solutions and showcase your brand's dedication to quality and eco-conscious practices.

PROCUREMENT CHECKLIST

Selecting the right packaging is crucial for customer satisfaction and operational success. A systematic approach ensures that businesses choose containers that protect food quality and align with brand identity. This checklist simplifies the decision-making process for purchasing to go boxes for food.

CHOOSING TO GO BOXES FOR FOOD

The menu dictates the type of container needed. Mismatched packaging can lead to soggy food, spills, and a poor customer experience. Businesses should evaluate their options based on the specific characteristics of their dishes.

-

Assess Food Temperature and Texture: Hot foods require different materials than cold foods. For fried items like chicken, vented containers are essential. Vents allow steam to escape, which prevents moisture buildup and keeps food crispy. For hot and wet foods like stews or pasta, a tall, narrow container with a secure, leak-proof lid minimizes heat loss and prevents spills.

-

Consider Wet vs. Dry Items: Soups and curries need leak-proof and oil-resistant containers. Kraft paper bowls with a PLA or PE lining are excellent choices. For combo meals, compartment containers made from materials like bagasse prevent flavors from mixing. Dry items like sandwiches have more flexible packaging options.

-

Match Container to Portion Size: Using the correct size for to go boxes for food is important. Oversized containers can make portions look small and allow food to shift during transit. Undersized containers lead to messy, unappealing presentation.

Pro Tip 💡 Always separate wet and dry components when possible. Providing dressings or sauces in separate, smaller containers is a simple way to preserve the quality of a meal during takeout and delivery.

BUDGET AND BRANDING GOALS

Cost and brand image are equally important in procurement. While budget is a primary concern, the cheapest option is not always the best. Businesses must analyze the return on investment for premium or sustainable packaging.

A recent study found that 68% of consumers are more likely to buy from a restaurant that uses sustainable packaging. This consumer preference can directly translate to increased sales. Products with sustainability messaging have seen sales growth of 28% over five years. Investing in eco-friendly to go boxes for food, such as those from Jolly Chef, can enhance brand perception and attract environmentally conscious customers.

Custom branding also offers a significant return. Well-designed packaging strengthens brand recognition and can increase in-store sales by up to 30%. To calculate the ROI, a business should track sales before and after a packaging change and measure metrics like customer loyalty. The initial costs for design and setup are often offset by long-term gains in customer retention and market position.

Successful takeout procurement balances material performance, operational cost, and brand identity. There is no single best container for every business. The ideal to go boxes for food are the best fit for a specific menu, budget, and company values, with brands like Jolly Chef offering diverse options. A smart choice improves the customer's takeout experience and supports business goals.

Use the procurement checklist to systematically evaluate your options. This will help you make a confident purchasing decision.

FAQ

What is the best material for hot foods?

Polypropylene (PP) plastic is a great choice for hot foods. It has a high heat tolerance and is often microwave-safe. Aluminum containers also excel at heat retention. For soups, lined kraft paper bowls, like those from Jolly Chef, work very well.

Are custom branded boxes worth the cost?

Custom branding turns a simple box into a marketing tool. It strengthens brand recognition and can increase customer loyalty. Businesses should weigh the initial setup fees against the long-term value of improved brand perception and potential sales growth.

Why should a business choose eco-friendly containers?

Eco-friendly containers appeal to environmentally conscious consumers. Using materials like sugarcane bagasse shows a brand's commitment to sustainability. This choice can improve public image and attract a wider customer base, boosting sales.

How can a restaurant test new containers?

Businesses should request samples from suppliers before placing a large order. They can test the containers with their specific menu items. This helps check for leaks, heat retention, and how well the food travels to ensure customer satisfaction.