Guide to Bulk Takeout Packaging

Choosing the right bulk takeout packaging is a critical decision in the modern restaurant industry. Your choice directly impacts food quality, customer satisfaction, and profitability. You must develop a smart takeout packaging strategy to succeed. This involves balancing your menu's specific needs against the performance and cost of different takeout containers.

The global market for online food delivery and takeaway continues to grow. This makes the customer experience for takeaway orders more important than ever.

A strong takeout packaging strategy helps you select the best restaurant takeout containers from the vast food packaging industry.

Key Takeaways

Choose takeout containers that fit your food. Hot soups need leak-proof containers. Fried foods need vents to stay crispy. Cold foods need to stay cool and dry.

Pick the right material for your containers. PET plastic is for cold food. PP plastic is safe for hot food and microwaves. Aluminum is great for oven-safe meals. Sugarcane containers are good for the environment and can handle heat.

Think about more than just the container price. Consider how much it costs to store, ship, and use the packaging. Buying in bulk can save you money.

Your takeout packaging is a way to show off your brand. You can add your logo to make your business stand out. This helps customers remember you.

Choose packaging that is easy for your staff to use and store. Also, pick eco-friendly options. Many customers like businesses that care about the environment.

MATCHING YOUR MENU TO RESTAURANT TAKEOUT CONTAINERS

The food you serve dictates the packaging you need. A container that works for a salad will fail for a hot soup. You must align your packaging choices with your menu to protect food integrity and deliver a great customer experience. This section breaks down the best containers for different types of dishes.

FOR HOT SOUPS AND SAUCY DISHES

Hot liquids present two main challenges: leaks and heat loss. You need a container that guarantees safety and keeps the meal hot from your kitchen to the customer's table. A spill not only creates a mess but also ruins the dining experience.

Look for materials with high temperature resistance and a leak-proof design. The right container provides excellent functionality and peace of mind.

High Temperature Resistance |

Leak-Proof Design |

Key Benefits |

|

|---|---|---|---|

Kraft Paper |

Microwave-Safe |

Yes (with secure lid) |

Eco-Friendly, Insulated |

Stainless Steel |

Insulated (Keeps Hot) |

Yes (with secure lid) |

Durable, Reusable, Insulated |

Glass |

Microwave & Dishwasher Safe |

Yes (with secure lid) |

Health Safety, Odor Resistant |

Paper soup bowls are very effective at regulating temperature. Many designs use double-wall insulation to trap heat, keeping soup hot for 30 to 60 minutes. For a reliable takeaway solution, consider the Jolly Chef Brown Microwavable Round Kraft Paper Soup Containers. Their premium kraft paper construction features a built-in polyester film, making them waterproof and oil-resistant. The secure, tight-fitting lids prevent leaks, ensuring a perfect delivery every time.

Pro Tip: You can extend heat retention even further. Pre-heating your containers with hot water before filling them reduces initial heat loss. Also, filling containers as full as possible minimizes airspace and slows cooling.

FOR FRIED AND CRISPY FOODS

Nothing disappoints more than soggy fried chicken or limp french fries. The enemy of crispy food is steam. When you seal hot, fried items in a non-vented container, the trapped moisture turns them soft and unappetizing. The right takeout packaging is essential for a good takeaway experience.

Vented containers are the solution. These containers have small holes or specially designed vents that allow steam to escape. This process releases moisture while retaining heat, preserving the food's intended texture.

U-Vent Designs: Some foam containers feature a "U-Vent" that lets steam out, keeping items like loaded fries crispy.

Vented Lids: Many plastic containers, like Clover™ or ProView™ products, come with vented lids that maintain freshness and crispness during transport.

Specialized Materials: Genpak® foam containers offer great insulation with vented lids, providing a durable option for fried foods.

Choosing the right packaging options ensures your fried dishes arrive as crispy and delicious as they were when they left your kitchen.

FOR COLD MEALS AND SALADS

For salads, poke bowls, and other cold dishes, your goals are to maintain a cool temperature and prevent sogginess. You need takeout food containers that offer good insulation. Materials like Expanded Polystyrene (EPS) and Polyethylene panels are effective, but you must also consider their environmental impact and storage costs.

Condensation is another major issue. It can wilt greens and make other ingredients lose their freshness. Preventing it is key to food safety and quality.

You can take several steps to avoid condensation:

Cool Foods First: Allow any warm components to cool completely before sealing the container. This simple step prevents steam from forming.

Use Moisture Absorbers: For very sensitive items, a food-safe desiccant pack can absorb excess moisture.

Apply Coatings: Some containers have anti-fog or condensation-resistant coatings that keep the interior dry and the lid clear.

Ensure a Tight Seal: Use containers with airtight lids to stop humid outside air from getting in.

FOR MULTI-COMPARTMENT MEALS

Bento boxes and other multi-compartment meals require containers that keep ingredients separate. This design is crucial for preserving the distinct flavor and texture of each component. You prevent sauces from making main courses soggy and stop strong flavors from mixing.

High-quality disposable takeout containers feature tight seals between compartments to prevent leaks and flavor transfer. This functionality is vital for dishes that combine wet and dry items. For very liquid components like dressings or soups, it is often best to use a separate, smaller container.

These containers also help you with portion control.

By using compartments, you can standardize portion sizes. This practice helps manage food costs by preventing the overuse of ingredients. It also ensures every customer receives a consistent and satisfying meal, which improves their overall impression of your brand. Over 75% of diners actually prefer smaller, well-managed portions.

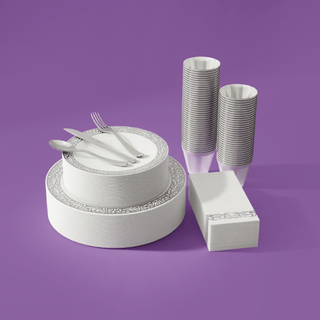

FOR GRAB-AND-GO AND TAKEAWAY ITEMS

For grab-and-go items like sandwiches, salads, and parfaits, presentation and convenience are everything. Your packaging needs to be easy for customers to pick up, carry, and eat from. This is especially important for businesses with high-volume takeaway traffic or drive-thru and delivery capabilities.

Product visibility is a major factor in boosting sales.

Clear Lids: Containers with clear lids allow customers to see the freshness and quality of the food inside. This transparency builds confidence and encourages impulse purchases.

Windowed Boxes: Sandwich or pastry boxes with a clear window highlight the product, making it more appealing on the shelf.

Secure Closures: A reliable locking mechanism is essential. It prevents spills during transport and gives customers confidence in the packaging.

Ultimately, the right container for grab-and-go items makes the food look great and provides a seamless takeaway experience for your busy customers.

COMPARING MATERIALS FOR TAKEOUT PACKAGING

After matching your menu to container types, the next step is to evaluate the materials themselves. Your choice of material affects food quality, operational costs, and your brand's environmental image. You need to understand the pros and cons of each option to find the perfect fit for your business. This section compares the most common materials used for restaurant takeout containers.

POLYPROPYLENE (PP) AND PET PLASTICS

Plastic containers are popular for their durability, clarity, and affordability. The two most common types you will encounter are Polypropylene (PP) and Polyethylene Terephthalate (PET). While they may look similar, their performance with heat is very different. This difference is crucial for the safety and quality of your takeaway meals.

PET is excellent for cold applications. You often see it used for salad bowls, beverage cups, and fruit containers. However, it has a low heat tolerance. A typical microwave heats food to around 212°F, but PET containers can start to warp or melt above 160°F. You should never use them for microwaving or for holding very hot foods.

PP, on the other hand, is built for heat. This material is ideal for hot entrees, soups, and any meal a customer might want to reheat. It offers superior stability and functionality for a wide range of hot takeaway dishes.

Material |

Safe Temperature Range |

Notes |

|---|---|---|

PET |

Up to 160°F (71°C) |

Not recommended for microwaving. Best for cold foods or gentle reheating. |

PP |

Up to 250°F (121°C) |

Excellent for microwaving. Retains its shape with hot, oily, or sugary foods. |

PAPER AND CARDBOARD SOLUTIONS

Paper and cardboard offer a classic and often eco-friendly look for takeaway packaging. They are lightweight, easy to store, and can be customized with your branding. However, standard paper has limitations, especially when it comes to holding heavy or moist foods.

Moisture Issues: Uncoated paper absorbs moisture. This can weaken the container and compromise the texture of the food inside.

Limited Strength: Compared to plastic, paper is more likely to bend or tear under the weight of heavy items.

To solve these problems, manufacturers apply special coatings. Early versions used wax, but modern packaging options rely on advanced, food-safe barriers. These innovations improve functionality without a negative environmental impact. New solutions include silicone-based coatings, plant-based biopolymers, and other fluorochemical-free treatments that provide excellent grease and moisture resistance.

JOLLY CHEF KRAFT PAPER CONTAINERS

For a paper solution that delivers exceptional performance, you can turn to specialized products designed to overcome traditional weaknesses. The Jolly Chef Brown Microwavable Round Kraft Paper Soup Containers are a perfect example of high-functionality paper packaging.

These containers are engineered for hot and saucy dishes. They are made from premium kraft paper with a built-in polyester film, which creates a waterproof and oil-resistant barrier. This design ensures your soups, stews, and curries arrive without leaks. The secure, tight-fitting lids lock in heat and prevent spills during transport, giving you and your customers peace of mind. Their microwave-safe nature adds a layer of convenience that makes them a top choice for any hot takeaway menu.

ALUMINUM FOIL CONTAINERS

When you need packaging that can go directly from the kitchen to a customer's oven, aluminum is the undisputed champion. It is perfect for "take-and-bake" meals, large pasta dishes, and roasted entrees.

Aluminum's greatest strength is its incredible heat tolerance. Aluminum foil containers can withstand any temperature a conventional oven can produce. They are also safe for use under a broiler, which typically operates between 500°F and 550°F. This versatility allows you to offer customers the convenience of reheating their meals without transferring them to another dish. While aluminum disposable takeout containers often have a higher per-unit cost than plastic, their unique oven-safe functionality provides significant value for specific menu items.

SUGARCANE (BAGASSE) AND PLA BIOPLASTICS

If sustainability is a top priority for your brand, you should explore bioplastics. The two main players are sugarcane (also known as bagasse) and PLA. Both are made from renewable plant resources, offering a great story for your brand. However, they serve very different purposes.

PLA has limited heat resistance, making it unsuitable for hot foods. Bagasse, a byproduct of sugarcane processing, is strong, durable, and handles heat exceptionally well. This makes it a fantastic material for all types of takeaway meals.

Container Type |

Heat Resistance |

|---|---|

PLA Bioplastic |

Limited, unsuitable for very hot foods |

Sugarcane (Bagasse) |

Strong, holds hot/oily foods, microwave-safe |

Did You Know? A majority of U.S. consumers—around 72%—view compostable packaging as extremely sustainable. Many are even willing to pay a small premium for it, which can offset the higher material cost.

For a product to be truly compostable, it must meet strict standards like ASTM D6400 and earn a BPI certification. This ensures it will break down completely in a commercial facility without leaving toxic residue. Choosing certified products is key to effective waste reduction strategies and maintaining the integrity of your sustainability claims.

For a premium, certified compostable option, consider Jolly Chef's Eco-Friendly White Compostable Food Containers. Made from sugarcane (bagasse), these containers are sturdy, microwave-safe, and feature a double-locking clasp to keep food secure. They represent a powerful investment in both food quality and your brand's commitment to the environment, making them an excellent choice for caterers and restaurants focused on sustainability. These sustainable packaging solutions help you meet customer expectations and reduce your environmental impact.

DEVELOPING YOUR TAKEOUT PACKAGING STRATEGY

You have matched your menu to containers and compared materials. Now you must build your takeout packaging strategy. This final step connects your packaging choices to your business goals. A successful takeout packaging plan balances cost, branding, and efficiency. This creates a great customer experience and supports your bottom line. Your takeout packaging strategy is a vital part of your business.

COST ANALYSIS AND BULK SAVINGS

You must first understand the total cost of your packaging. The price per container is only one part of your takeout packaging strategy. You can often lower this price significantly. Buying in bulk can reduce your per-unit costs by up to 30%. This is a key part of a successful takeout packaging plan.

However, a smart takeout packaging strategy looks at the Total Cost of Ownership (TCO). You need to calculate all related expenses.

Materials and Manufacturing: The direct cost of the containers.

Labor: The cost of staff time to assemble and fill packaging.

Shipping: The expense to get the packaging to your restaurant.

Warehousing: The cost of storing your inventory.

Damaged Inventory: The cost to replace damaged packaging.

Storing a single pallet of packaging can cost you $32 to $48 per month in a rented space. This shows how storage adds to your TCO over time. A good takeout packaging strategy minimizes these hidden costs.

BRANDING AND CUSTOMIZATION

Your takeout packaging is a mobile billboard for your brand. A strong takeout packaging strategy uses this to your advantage. Custom printing turns a simple box into a powerful marketing tool. It helps your brand stand out and creates a memorable customer experience.

You do not always need a huge budget for customization. Many suppliers offer custom printing with low minimum order quantities (MOQs). For example, you can often order as few as 100 custom takeaway boxes. This makes branding accessible even for smaller businesses. A thoughtful takeout packaging strategy includes these branding opportunities. This customer-centric design improves the overall takeaway experience.

OPERATIONAL AND STORAGE EFFICIENCY

Your packaging choices directly affect your kitchen's workflow. A successful takeout packaging plan considers operational speed and storage space. Your takeout packaging strategy must improve functionality. Containers that are hard to assemble or close will slow down your staff during busy hours. This can lead to longer wait times for your customer.

You should choose packaging options that are easy to stack and store. This maximizes your limited storage space and keeps your kitchen organized. Good functionality ensures your team can prepare takeaway orders quickly and correctly. This focus on packaging effectiveness is a core part of a smart takeout packaging strategy.

SUSTAINABILITY AND BRAND IMAGE

Sustainability is more than just a trend. It is a core part of a modern takeout packaging strategy. Your choices about the environment impact how customers see your brand. Research shows that 63% of consumers find eco-friendly packaging important. A focus on sustainability can build trust and loyalty.

Adopting sustainable practices shows your commitment to reducing waste. This resonates with a growing number of consumers. In fact, 54% of consumers are willing to pay more for sustainable products. This can help offset the higher cost of some eco-friendly materials. Your waste reduction strategies and commitment to sustainability become a competitive advantage.

A successful takeout packaging plan starts with your menu, then materials, and finally your business goals. The ideal restaurant takeout containers preserve food quality, align with your brand, and improve the customer experience. With many consumers willing to pay more for sustainable options, your takeaway packaging strategy is a key investment.

Use these insights to create a simple checklist. This will help you evaluate suppliers and make a confident decision for your takeaway business, ensuring a great customer experience. A successful takeout packaging plan supports your brand and delights every takeaway customer.

FAQ

What is the most important factor when choosing takeout packaging?

You should always start with your menu. The type of food you serve dictates the container's material and design. This ensures food quality and customer satisfaction. Matching your menu to the container is your first and most critical step.

Can I microwave all plastic takeout containers?

No, you cannot microwave all plastics. PET plastic is for cold foods and can melt in the microwave. You should only use PP (Polypropylene) containers for hot foods and reheating. Always check the container's specifications for safety.

Is custom branding on packaging expensive for a small business?

Custom branding can be affordable. Many suppliers offer custom printing with low minimum order quantities (MOQs), sometimes as few as 100 units. This makes branded packaging an accessible marketing tool for businesses of all sizes.

What makes a container truly compostable?

A truly compostable container must break down completely in a commercial facility. You should look for official certifications like ASTM D6400 or BPI. These certifications guarantee the product meets strict environmental standards for composting.

Pro Tip: Using certified compostable products like Jolly Chef's sugarcane containers strengthens your brand's eco-friendly image and builds trust with customers.